We have our own tool shop and design department, thus we are able to carry out the entire process in-house – from 3D modeling, through injection moulding to batch production of finished parts. Working with us is a guarantee of an end-to-end approach: from the idea to the finished product. We never outsource any production stage, therefore we have full control over quality, costs and deadlines. This is why we are able to offer our customers products made with precision, according to their order and expectations.

Production partnership with SIGERN covers the entire execution process – from design and modelling, through tooling preparation, to production and shipment of finished plastic or aluminium parts directly to the customer. Our offer is tailored to companies seeking a professional and end-to-end production service – with a guarantee of quality, timeliness and full commitment.

Many years of experience in plastics processing and partnership with companies in different industries make us confident in managing demanding and unusual projects. Our portfolio also includes implementations protected by patent claims, which were developed based on our original concepts and completed in cooperation with customers.

We make every effort to ensure that the components delivered to customers fulfil all quality and functional requirements, while meeting industry standards. The confirmation of our reliability and effectiveness are testimonials of satisfied customers.

We perform all stages of production at our production facility in Poland, therefore we have full control over every process. Hance we can demonstrate to the customer the entire process of product creation – step by step, from the design to the final product.

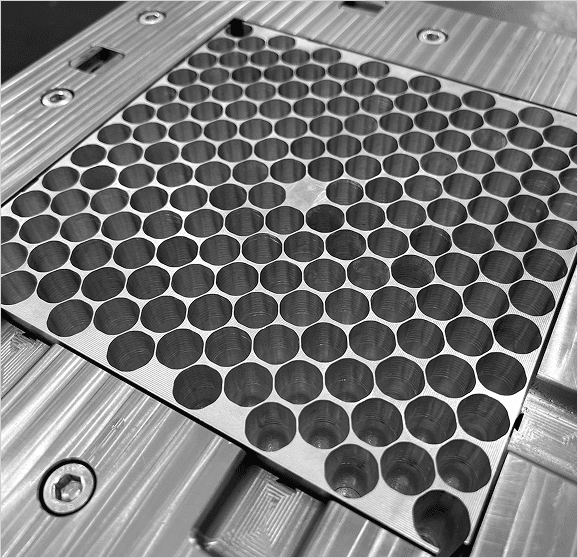

We keep investing in production automation. Our tool shop features state-of-the-art milling machines and EDMs, used in precise production of injection moulds. We use electric injection moulding machines with manipulators for production of parts as well as a system for automatic system for granule dosing and drying granules, to ensure optimum quality and production efficiency.

CNC machining is the basic technique for producing parts and tools made of steel and plastic by machining. It features exceptional precision, achieved by using advanced computer programs.

The CNC machining process is carried out with a range of different tools, such as milling machines, lathes, cutters and grinders, used to machine small pieces of material and shape parts according to project requirements. Importantly, machining can not only produce the desired shape, but also can smooth the edges, which is crucial from both technical parameters as well as the aesthetics of the product.

Before machining begins, dedicated software analyses the type of material and its roughness, while taking into consideration customer’s expectations, so that process parameters can be fine-tuned to meet technical and quality requirements.

ETAPY WSPÓŁPRACY

Having many years of experience in plastics processing, we became experts not only in manufacturing injection moulds, but also in end-to-end handling of projects, where injection moulding is carried out at our site. Our batch production of plastic and aluminium components is done using both injection moulds fabricated by us and on moulds entrusted by the customer.

We provide a full range of services – mould design, fabrication and maintenance, if the injection moulding service is performed in our injection moulding room. With state-of-the-art processing facilities and our own tool shop we can guarantee precise manufacturing, high quality and reliability of our products.

Our customers include both smaller, local companies and large enterprises, and we customise moulds to meet specific production needs.

The mould fabrication process starts with a detailed consultation with the customer to understand all the requirements for the project. Along with the customer we analyse expectations regarding the final product, material and production technology. Our expertise is in designing injection moulds for plastics and aluminium, hence we are able to offer solutions for the most demanding industries.

Because we use modern CAD/CAM tools and injection moulding simulation software, we can ensure high precision of the moulds we design, optimising them for durability and production efficiency. Our technology helps avoid construction errors, ensuring that the mould when finished needs no re-fabrication.

The entire production process takes place in our tool shop, giving us full control over every stage. Our plastic and aluminium injection moulds feature long service life, which ensures stable and reliable production.

If production if carried out at our facility, we offer maintenance of injection moulds. We keep injection moulds fully operational, by re-fabrication, maintenance and repair. Regular maintenance and modifications of moulds help avoid unplanned downtime and extend service life of the mold.

As a Polish manufacturer of injection moulds, we provide European quality and the highest production standards. Having our tool shop, state-of-the-art machinery and full control over the production process, we are able to offer a complex service – from mould design, through mould fabrication to maintenance of moulds. For our customers this means confidence in the quality, timeliness and efficiency of production.

If you seek an injection mould that is professionally made and a one-stop shop for batch production of parts, get in touch. We offer expert advice, personalised approach and full technical support at every stage of cooperation.

If you need a professionally made injection mould and tool manufacturing service, but also batch production of parts in one place, contact us. We offer personalised approach, expert advice and full technical support – from design through production to maintenance. Check what we can do and see why so many customers have already trusted us!

Firma Produkcyjno-Handlowo-Usługowa SIGERN Wojciech Fałowski Sp. K.

NIP: 734 305 22 99

REGON: 492946256

KRS: 0000474793

Reques a QUOTE

We will create an injection mould for you and handle the production.

Please contact the desired department.

Wir sind international tätig. Wählen Sie diese Option aus, um die Seite in der entsprechenden Sprache anzuzeigen.