We operate in international markets, delivering European quality and reliability in every detail. We ensure timely and safe delivery, in the highest standards of logistics and customer service.

It was 24 August 2004 when brothers Piotr and Wojciech Fałowski decided to enter the world of plastics processing. They launched their business having one, second-hand used injection moulding machine and a great deal of determination. Initial years was the time of intensive knowledge building, daily financial challenges and gathering experience in a dynamic environment.

Our fresh approach, commitment and reliability helped us win trust of customers, followed by numerous orders and long-term business relationships. In 2016 Kamil Fałowski, another brother, joined the team and passionately started to expand the tool shop, bringing new energy to one of our key business areas. The injection moulding room operates on a schedule under the watchful eye of Piotr Fałowski, while the design department – led by Wojciech Fałowski – is driven by creative and innovative solutions. With annual investments in machinery and automation we were able to greatly increase production capacity and expand our offer, maintaining at the same time a stable team.

Today, SIGERN stands for state-of-the-art manufacturing space, innovative approach and continuous development that drives our business every day.

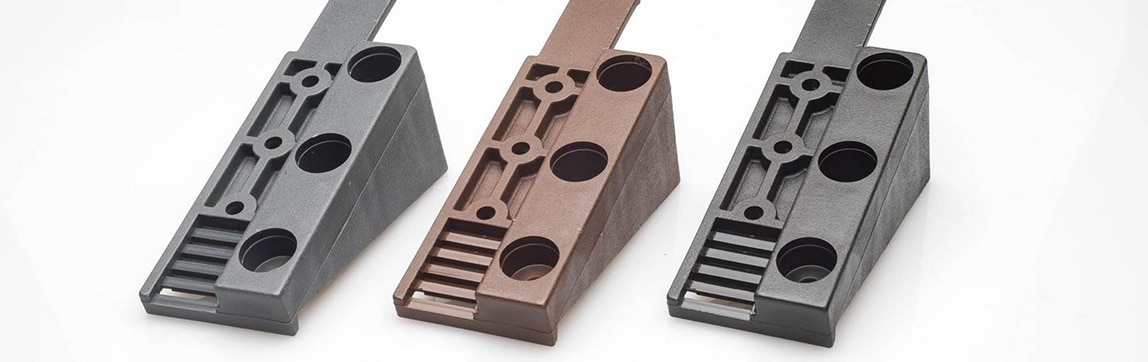

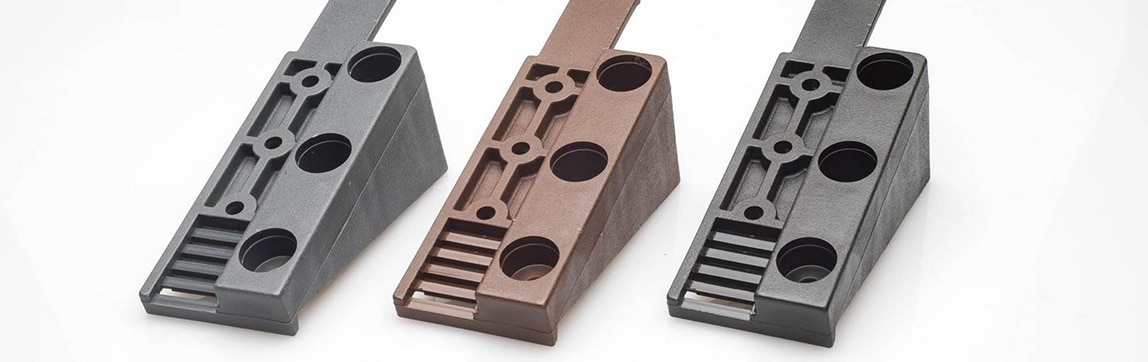

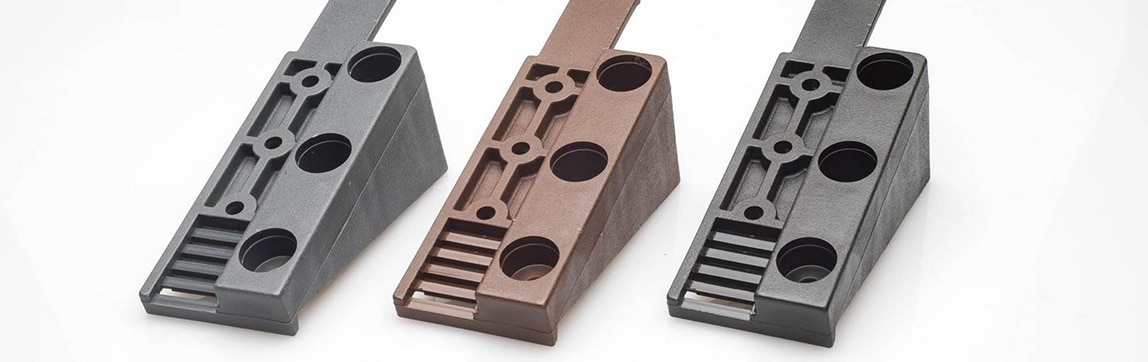

SIGERN was created through passion and family cooperation. From the very start our goal was to create highest quality components to meet even the most demanding expectations. We focus on modern technologies, sustainable raw materials and optimisation of production.

We are not afraid of challenges – rather than following the conventional way of doing business, we took a creative approach hence we are able to effectively support customers in delivering innovative projects.

Ecology, innovation, precision. We create components of the future.

Years of experience in the industry made us realise that being successful requires a synergy of knowledge, modern technology and full commitment. Our team are experts who develop the company on many levels – from design and implementation to production and process optimisation.

With our own tool shop, modern machinery and innovative work methods, we create solutions appreciated both in the domestic and international markets.

We combine experience with design creativity to come up with solutions that stand out in the market.

At SIGERN, quality is not just a standard – it is the foundation of our business. Every stage of production, starting with design and selection of raw materials to final production, is thoroughly inspected.

We operate a modern machinery park and own tool shop and hold ISO 9001 and ISO 14001 certificates, as confirmation that our processes are consistent with the highest quality and environmental standards.

We focus on new technologies, an environmentally sustainable approach and partnerships with customers. Result? Since the start of our business we never lost a single client.

Quality, technology, trust – these are the pillars of cooperation with SIGERN.

We have implemented and pursue an Integrated Quality and Environmental Management System in accordance with the requirements of PN-EN ISO 9001:2015 and PN-EN ISO 14001:2015. This confirms that SIGERN is a credible business partner and sets the direction we are consistently heading.

As part of our environmental efforts, we have introduced a number of improvements to reduce the impact of our production on the environment. We also use renewable energy sources, in our strategy of sustainable development.

Our end-to-end production partnership offer also covers both re-fabrication and maintenance of injection moulds. We provide full technical support at every stage of the mould life cycle so that the highest production quality is maintained and downtime minimised

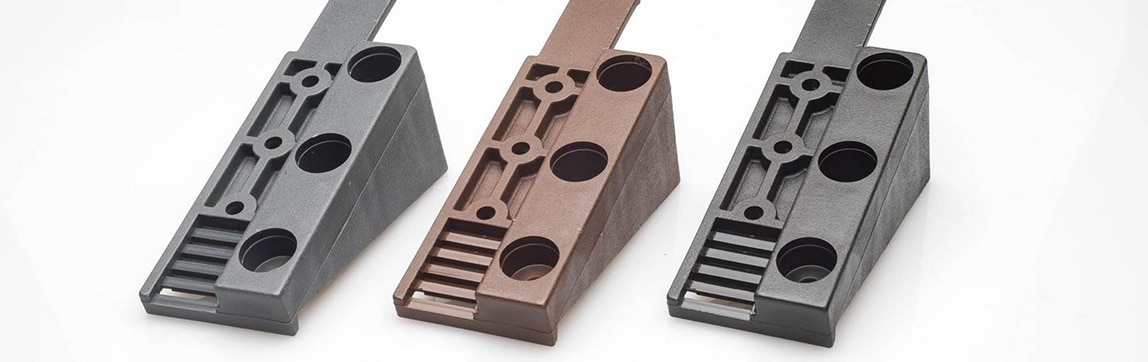

We use a range of different plastics in our production, including polystyrene (PS), polypropylene (PP), polyethylene (PE), polyamide (PA), polyacetal (POM) and thermoplastic elastomers (TPE). We also execute projects using aluminium alloys

You are welcomed to contact us – we will be pleased to advise on the selection of materials, product functionality and shape optimisation to best fit the solution to your needs.

In addition to the execution from scratch, our other model of cooperation involves batch production on moulds entrusted by the customer. The mould remains in our facilities and is used to fulfil customer’s orders, thus ensuring continuity of production and full control over the process.

Our offer is end-to-end – from design, through fabrication of the mould and test injections, to batch production. The moulds we make are only used for production at our facilities – we do not just sell injection moulds which would then be used with other suppliers.

Yes, we will make a prototype if needed. Prototyping is an integral part of the design and modelling process, a stage at which concepts are scrutinised before batch production launch.

Typical lead time is between 5 and 14 weeks and it depends on the size and complexity of the moulded part.

The service life of an injection mould, or the number of production cycles it will last, while maintaining the required quality standards, ranges from 100 000 to 1 500 000. That number depends on the materials used, the manner of demoulding and the type of plastic.

We only run repetitive production batches. The minimum order size is:

10 000 units per year for parts of less than 50 g,

5 000 units per year for parts between 50 and 120 g,

2 000 units per year for part of more than 120 g.

Nie znalazłeś odpowiedzi na swoje pytanie? Skontaktuj się z nami! Chętnie rozwiejemy wszelkie wątpliwości i pomożemy dobrać najlepsze rozwiązanie. Jesteśmy do Twojej dyspozycji!

Firma Produkcyjno-Handlowo-Usługowa SIGERN Wojciech Fałowski Sp. K.

NIP: 734 305 22 99

REGON: 492946256

KRS: 0000474793

Reques a QUOTE

We will create an injection mould for you and handle the production.

Please contact the desired department.

Wir sind international tätig. Wählen Sie diese Option aus, um die Seite in der entsprechenden Sprache anzuzeigen.